Update: The 100% E-Waste Collection Bill is under consideration now in The Minnesota legislature. Support for SF1690 and HF1426 is much appreciated!!!

Q: What do you mean 68 elements...? I am a recycler, and we only recycle gold, silver, and copper from our scrap!

A: The pilot study was conducted to start a conversation about possibilities. We are aware that the current collection and recycling processes are not currently able to extract all elements found within our e-waste stream. The value reported in this study is aspirational – it is what we could have if it were possible to extract 100% of all the elements available.

Q: So how do we get there?

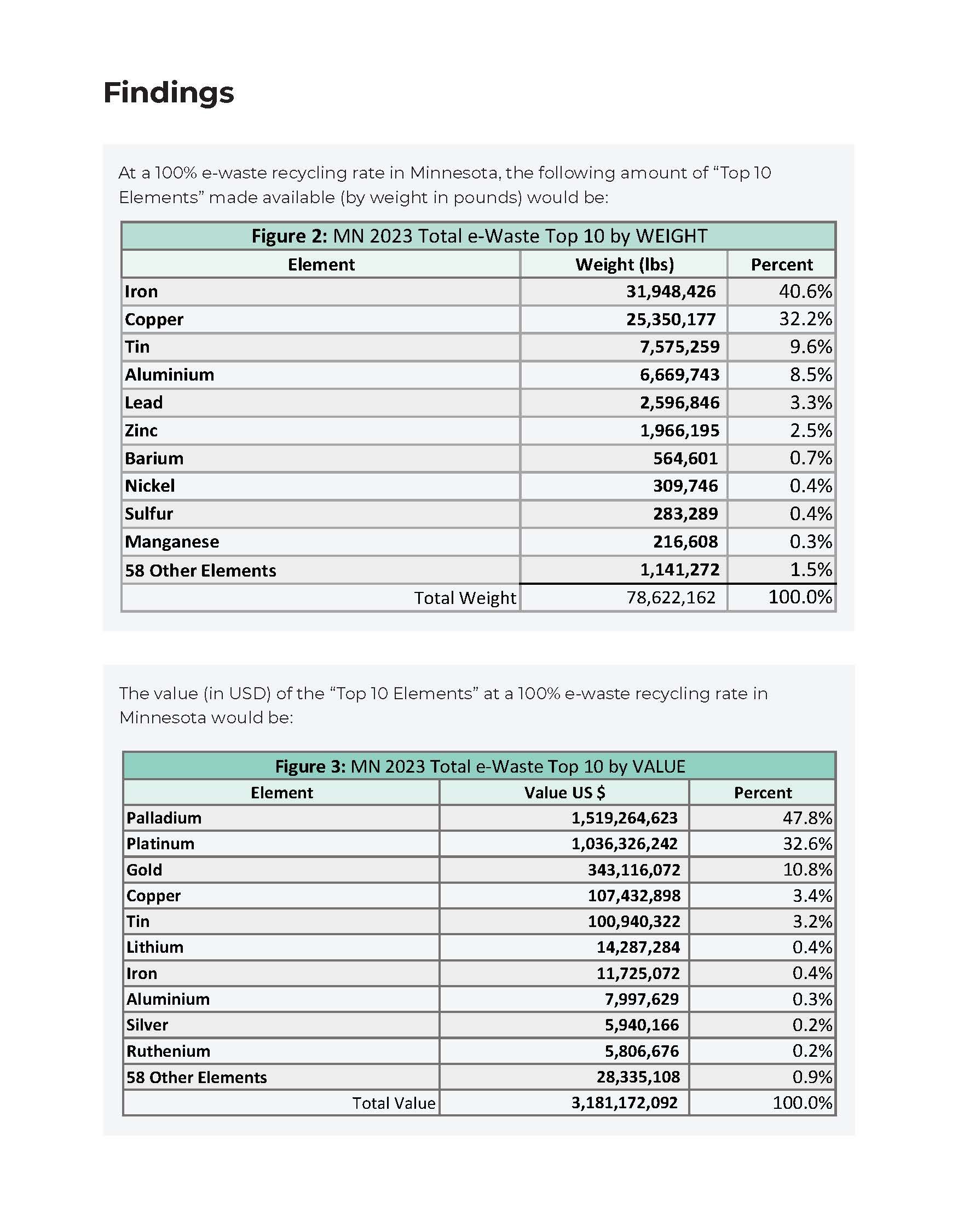

A: First, in MN we only collect 23.7% of our e-waste. The first step is to get closer to capturing 100%. Without that first step, we will continue to waste these valuable metals and contaminate our communities. A next step could be local investment in the processing of these materials, such as building additional shredding facilities, and it is never too soon to invest in research for better, more effective and environmentally sound methods of final material recovery so that a future e-waste economy in Minnesota could produce useable metals, instead of shipping them out of the country for smelting. All of these activities would generate thousands of local jobs and bring us much closer to capturing that estimated 3.2 billion dollars in elements.

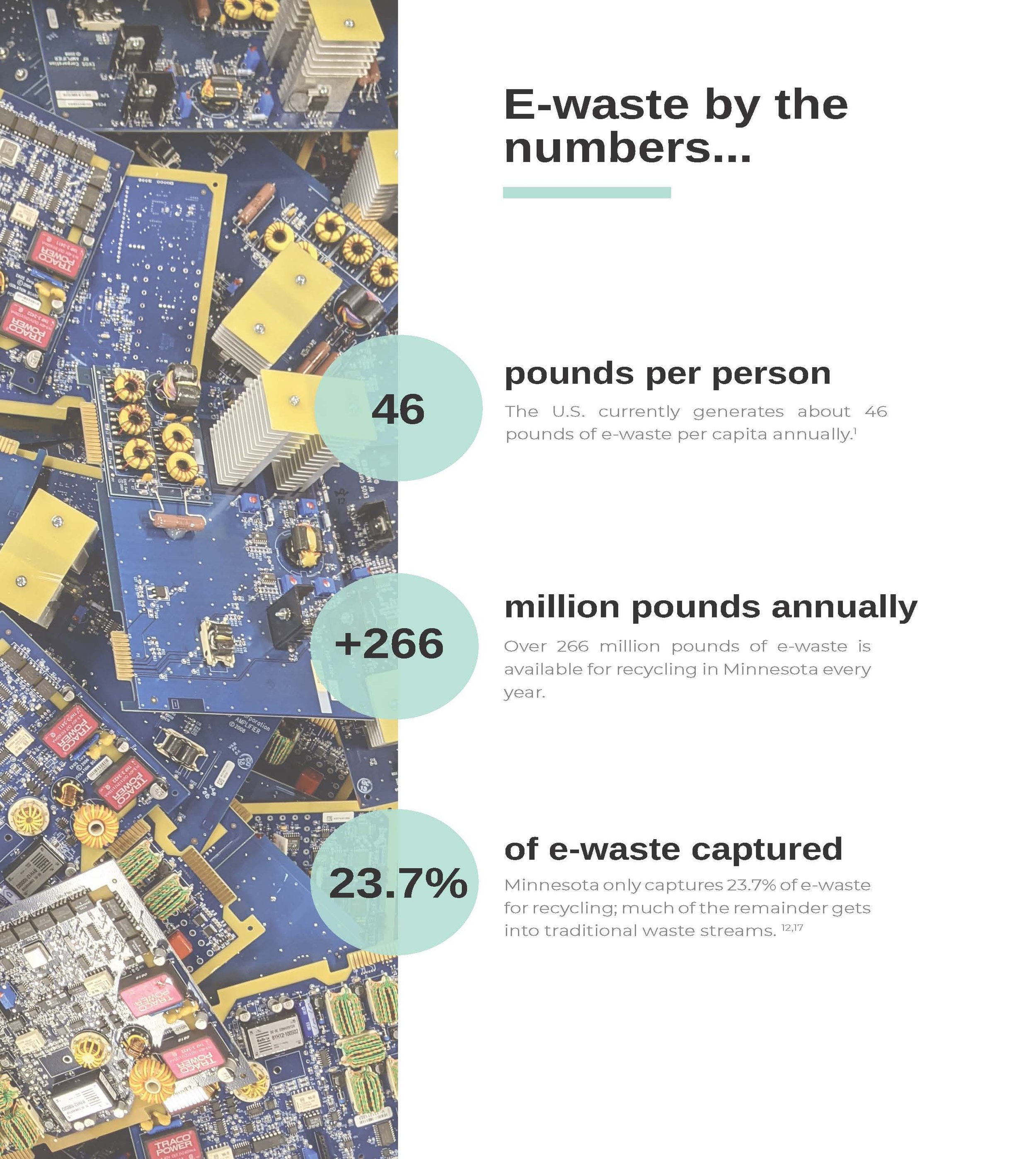

Q: 46 pounds per person? But I only have a laptop, a cell phone and a few appliances at home!

A: When the Global E-waste Monitor uses “per capita” generation of e-waste, they are aiming for a standardized method to compare different countries and regions. This does not mean that each individual (capita) in that region generates or throws away the named quantity of e-waste. It is a standardized measure for comparison only. For example, in North America, the E-waste monitor identifies 46 pounds of e-waste per capita. Not every baby and toddler and elder throws away 46 pounds of e-waste each year. Each of us does throw away quite a bit. But the e-waste generated by large businesses who have banks of servers being updated and replaced and hundreds of outdated computers and obsolete air conditioning systems count as e-waste too. Big box stores with outdated cash registers and scanning systems, medical facilities full of high-end electronics are part of a much larger cache of e-waste. The “per capita” unit is simply a way to compare counties and states and countries and continents. The North American continent stands at 46 pounds per capita. That includes every electronic waste item in the entire continent, divided by the population for a reference point.

Q: 482 dollars per person..? That seems way too high!

A: As with the “per capita” standardized figure, this represents the total value of e-waste divided by the population. It doesn’t mean that each person generates $482 worth of e-waste.

Q: You know, metals coming from e-waste are NOT the same quality as what you find on the London metals exchange, your value estimate is way too high!

A: Most metals are infinitely recyclable. It is true that metals and other recyclable elements in e-waste are not in the processed form that is traded on the London Metals Exchange (LME). The goal is a continuous cycle of trading/selling of refined metals for re-use in new electronic devices and products, the capturing of all e-waste by certified collectors, the disassembly, breakdown, and sorting by re-cyclers, processing by e-waste shredders and environmentally sensitive extractors, and the concentrating of the elements and refinement for resale on the LME. Currently all these steps are inefficient, expensive, and not particularly environmentally sensitive. The elements are there, and most can be reused indefinitely. But we need to invest in improving the processes for every step in the cycle to lower costs, improve the recovery of the metals, and do it with less environmental impact. Our study looks at the potential value of the content of the e-waste stream with an eye to encouraging the improvement of current processes and developing new processes to improve the extraction and lower costs. It does not reflect the current state of the art, but what can be potentially achieved with investment in the research and process development to reach the point where we can capture the potential of e-waste.

Q: $3.2 billion sounds wonderful, but it will cost something to extract that amount of metals, so that figure isn’t what we’ll net.

Absolutely correct. That’s why we’ve tried very hard to emphasize that this is the value of the metals available, not the net “profit” when extraction costs are deducted. There’s an excellent 2016 study from The Journal of Cleaner Production by Zeng and Li “Measuring the recyclability of e-waste: an innovative method and its implications” that tackles this challenge. Here’s the abstract:

“The viability of closed-loop recycling of electronics can sustain the future development of the flourishing electronics industry. Identification for the recyclability of e-waste (or WEEE) plays an enhanced role in process designing and policy making. However, precise measurements of recyclability, subjected to resource reclamation and environmental protection analysis, have not yet been well recognized. This study defines the rules of grade determination for various materials in any given WEEE, then combines these rules with the Statistical Entropy function, to develop an innovative model to measure the recyclability, emphasizing the product design stage, in order to significantly promote qualitative to quantitative eco-design. Using this model, not only e-waste recycling can be partitioned into three levels of difficulty, but also the measurement method can be employed to divide the responsibility for electronics recycling between producer and recycler.”

To request study, see https://www.sciencedirect.com/science/article/abs/pii/S0959652616305108

Relevant statements:

P157 “The term ‘recycling potential’ has been defined from an economic perspective, satisfying the requirement that potential e-waste recycling revenues exceed the costs of collection, transportation, and processing (Bartl, 2014; Dahmus and Gutowski, 2007; Graedel, 2011b). Owing to economic fluctuation and rapid technological innovation, however, recycling potential does not take into account the entire processing cost and thus cannot always reflect the nature of the recycling technology. Here we define recyclability as the theoretical probability of an item's actually being recycled, taking into account the recycling difficulty for metals, plastics and glass in physical treatment and chemical recovery (Fig. S1 of Supplementary content (SC)) (Villalba et al., 2002, 2004). The definitions and properties of recycling potential, recyclability, and recycling difficulty have been addressed in SC Text1. Therefore, the net recycling cost of WEEE depends upon its recyclability, not its recycling potential, which is only relevant to the concentration of recoverable materials within it. A comprehensive theoretical guide to recycling processes, quantitative eco-design, and recycling responsibility is quite essential to determine the authentic recyclability of e-waste. In this study, we create innovative mathematical models, based on the physical and chemical characteristics of materials contained in e-waste, to measure the recyclability and recycling difficulty of various types of electronics. We then analyze the differences among the various e-waste types and recycling scenarios, and endeavor to determine how each of them might contribute to the development of e-waste regulations, electronics eco-design, and recycling responsibility.”

How can I help move Minnesota forward? You can support the 100% collection bill in the Minnesota legislature right now. Both the MN House and Senate committees will hear the bill the week of March 4. SF3490 and HF3566. Contact your Senator and Representative!